In a modern business environment, downtime is more than an inconvenience—it’s a costly threat to productivity, revenue, and customer satisfaction. Whether you’re running a manufacturing facility, logistics operation, or IT infrastructure, equipment reliability is non-negotiable. That’s where Odoo 17’s Maintenance module comes in—a flexible, integrated tool that empowers organizations to take control of their maintenance strategies.

At Databit Limited, we specialize in deploying robust business management systems like Odoo ERP to ensure our clients maintain peak operational performance. In this article, we explore how Odoo 17 enables effective management of both preventive and corrective maintenance, and how you can leverage it to extend asset life, reduce costs, and increase productivity.

Understanding the Basics: Preventive vs. Corrective Maintenance

Before we dive into the functionality of Odoo 17, it’s essential to clarify the two primary types of maintenance:

1. Preventive Maintenance: Proactive and Strategic

Preventive maintenance is planned and performed regularly to minimize the risk of equipment failure. Think of it as the “health check-up” for your machinery or IT systems. By scheduling inspections, lubrication, adjustments, and minor repairs, you can avoid costly emergency repairs and unplanned downtime.

Key benefits of preventive maintenance include:

Extended equipment lifespan

Reduced frequency of major breakdowns

Improved safety for workers and systems

Predictable budgeting for maintenance costs

With Odoo 17, businesses can configure recurring maintenance tasks based on time intervals, usage metrics, or sensor data. This ensures that no component is neglected and all machinery is kept in optimal condition.

2. Corrective Maintenance: Responsive and Necessary

Corrective maintenance, on the other hand, is reactive. It is performed when equipment fails or malfunctions unexpectedly. While it’s not ideal to rely solely on this type of maintenance, it is crucial for restoring operations when something does go wrong.

Odoo 17 allows you to:

Instantly log a failure or issue

Assign the task to the appropriate technician or team

Track resolution progress through various stages

Document the cause, repair, and recommendations for future prevention

Together, preventive and corrective maintenance form the foundation of a resilient operations strategy—and Odoo 17 offers the right tools to balance both.

Exploring Odoo 17’s Maintenance Module Features

Odoo 17’s Maintenance app is intuitively designed and tightly integrated with other Odoo modules such as Inventory, Manufacturing, and HR. Below are some of its most impactful features:

1. Maintenance Request Dashboard

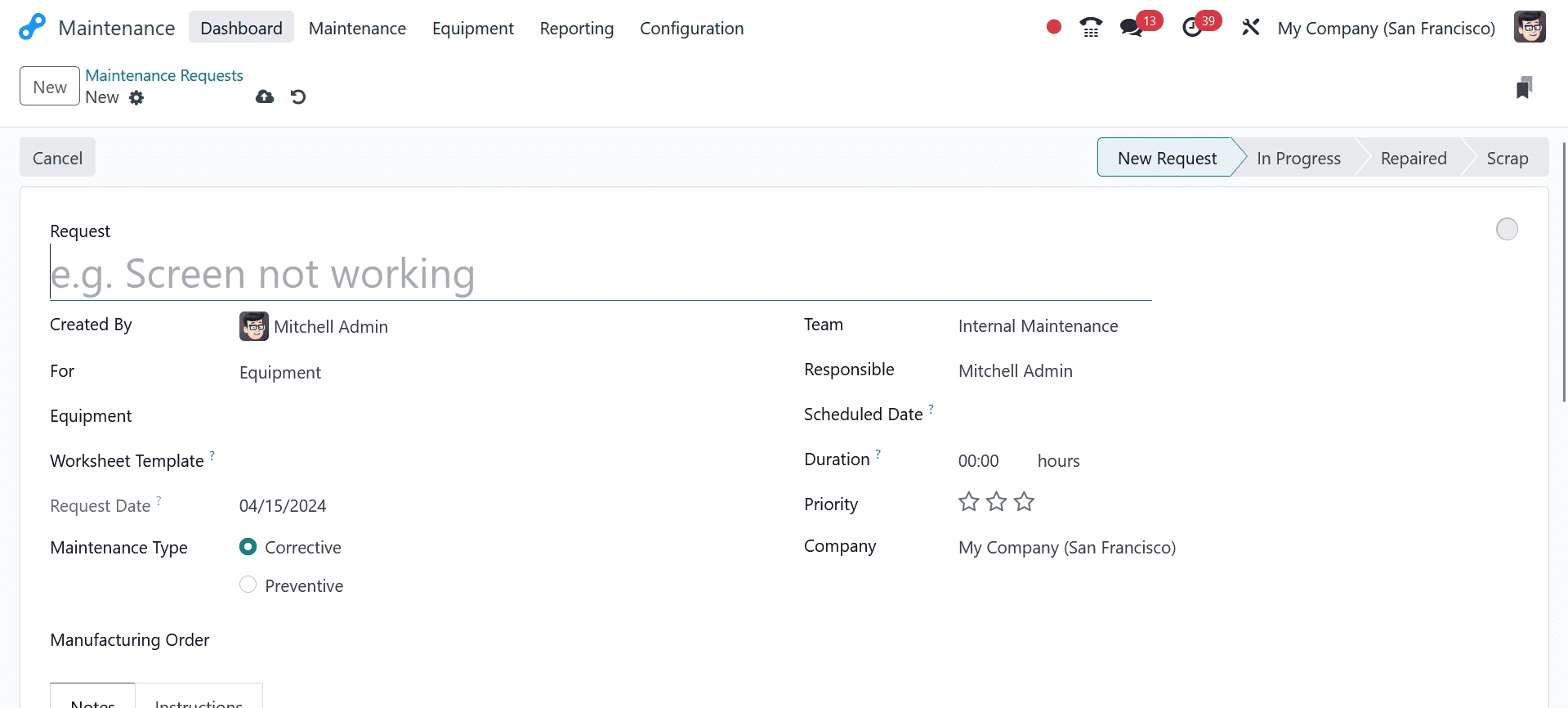

Users can create new maintenance requests in just a few clicks, providing essential details such as:

Equipment name and category

Maintenance type (preventive or corrective)

Priority level

Responsible team or technician

Scheduled or expected resolution date

The Kanban view allows you to visually track all requests, moving them through various stages like “New”, “In Progress”, “Repaired”, or “Scrapped”. Managers can also use calendar and Gantt views for better workload balancing and planning.

2. Automated Preventive Maintenance Scheduling

Odoo 17 supports smart scheduling based on frequency, usage, or custom rules. For instance, you can configure maintenance every 500 operating hours or once every 3 months. These recurring tasks are automatically generated and assigned, eliminating the need for manual scheduling.

This kind of automation significantly reduces human error and ensures equipment is maintained on time, every time.

3. Integration with Equipment Management

The Maintenance app is integrated with Odoo’s Equipment module. Each piece of equipment has a detailed record, including:

Manufacturer details and serial number

Location and responsible user

Maintenance history

Upcoming preventive maintenance dates

Downtime logs and performance issues

This comprehensive view helps technical teams make informed decisions and gives managers insights into asset health and utilization.

4. Analytical Reports and KPIs

Reporting is a major strength in Odoo 17. You can track KPIs such as:

Mean Time Between Failures (MTBF)

Mean Time to Repair (MTTR)

Number of maintenance requests per team or equipment

Time and cost spent on repairs

These metrics help you identify patterns, optimize maintenance schedules, and justify investments in new equipment or upgrades.

How Databit Limited Can Help

As an Odoo implementation partner, Databit Limited provides end-to-end support for deploying and customizing Odoo 17’s Maintenance module. We ensure it aligns with your specific operational needs, whether you’re managing production lines, IT assets, or fleet vehicles.

Our services include:

Business process mapping and consultation

Custom module configuration and workflow automation

User training and change management

Ongoing support and performance optimization

When your maintenance strategy is powered by a system as comprehensive as Odoo and supported by a partner like Databit, you’re equipped to minimize risk, boost uptime, and maintain operational excellence.

Why Maintenance Matters More Than Ever

In 2025 and beyond, businesses cannot afford the costs of reactive-only maintenance. Increased competition, tighter margins, and growing customer expectations make it essential to maintain every asset at peak performance.

A smart maintenance system not only prevents failures but also enables predictive insights, cost forecasting, and better alignment between operations and IT. Odoo 17’s Maintenance module, when correctly implemented, is the digital foundation for such a system.